Heereco Organic Mushrooms: producing mushrooms organically

Formerly known as Heeren Mushrooms, Heereco is a family business based in Uden, and was founded in 1971. The business is currently owned by Dorus and Jeffrey Heeren. In 2005, the brothers oversaw the switch to fully organic mushroom cultivation. Heereco consists of several mushroom farms, a composting facility for phase II and phase III compost production, and a drying facility which enables large quantities of organic mushrooms to be dried.

Mushroom substrate production

Heereco purchased an existing tunnel company based in Broekhuizen in 2016, which led to the creation of Heereco Compost. The composting facility consisted of nine pasteurisation and phase III tunnels. This purchase underlined their ambition to supply organic substrate to their own mushroom farms. To ensure the tunnels could be kept filled and used efficiently, the decision was taken to sell phase III compost to third parties. Due to the growing demand for both organic mushrooms and organic compost, Heereco saw opportunities to further increase the capacity of the composting facility. This led to the construction of six new tunnels in 2018. Each tunnel has a surface area of 176 m2 and a volume of 704 m3. Another three tunnels of the same size were added in 2021. This expansion increased the total production capacity to 650 tonnes of phase III compost per week.

Phase I compost is produced and supplied by CNC Moerdijk. The raw materials required, such as straw, chicken manure and gypsum are purchased by Heereco and delivered to CNC Moerdijk. Chicken manure is sourced domestically. A sufficient, local supply of organic straw is currently unavailable, and is therefore purchased from farmers in France and Germany. Straw is mostly supplied from within a 500 km radius. At Heereco Compost, two main mushroom varieties are used: the 737 strain from Sylvan for white button mushrooms, and the Heirloom from Amycel for chestnut mushrooms. Organic mushroom supplements from ChampFood International are added to the compost.

Heereco Compost currently produces about 600 tonnes of compost per week, of which 25% is intended for its own mushroom farms. The remaining 75% is sold to mushroom growers in the Netherlands, Germany, France, Switzerland and Denmark.

Mushroom production

Heereco has been growing mushrooms since 1971. Like many mushroom farms of that era, Heereco also began by filling growing beds with phase I compost. Fresh compost was supplied by CNC and pasteurising and conditioning were carried out in the growing rooms. After cooling, the compost was inoculated. Following a spawn run period of 14 days, the compost was covered with a layer of casing soil. About 15 days after casing, the first flush would be harvested.

Between 1971 and 2005, Heereco grew common mushroom varieties using conventional methods. The range consisted of white and chestnut mushrooms, later expanding to include varieties such as portobello, flat white and giant. Heereco took control of its own mushroom trading activities in 2000,

and transitioned to organic production in 2005. Today, organic mushroom growing remains their only method of production.

About 50% of Heereco mushrooms are sold on the domestic market with the rest being sold in Germany, France, Belgium and Scandinavia. Through partnerships with neighbouring growers, Heereco also offers its customers oyster, shiitake and eryngii (king oyster) mushrooms. As a result, Heereco offers a complete range.

The majority of the mushrooms are sold as fresh produce. Heereco built a drying facility in 2016, in which the mushrooms are processed and dried. The dried mushrooms are either sliced or processed into powder form. If sales of fresh mushrooms stagnate, the drying facility allows Heereco a degree of flexibility. It provides Heereco with a flexible, sustainable and largely cost-covering backup strategy and solution.

Heereco currently has a growing surface area of about 10,000 m2. Legro and BVB supply casing soil for use on the farms. On this growing surface area, Heereco produces 46 to 55 tonnes of mushrooms every week. Depending on mushroom sales, the farm uses a two or three flush cropping cycle. If sales are consistently good, a shorter, faster cycle is used. If sales are slower, then Heereco picks a third flush. Heereco added a new mushroom growing facility to its operations in July 2022. The new Christiaens growing facility has been built next to the existing facility in Uden. As in other primary sector activities, mushroom cultivation is increasingly reliant on automation.

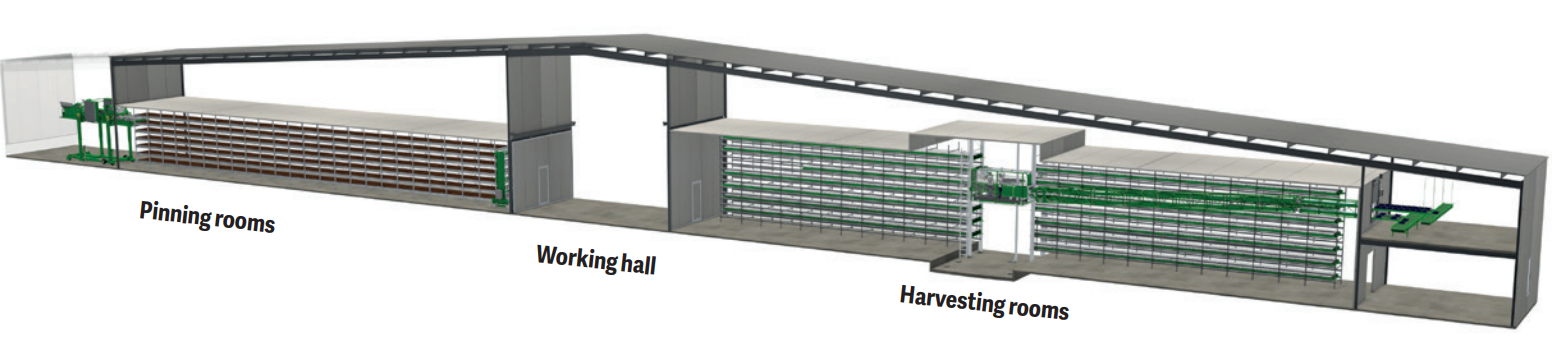

The new facility includes a new growing/harvesting system, the so-called drawer system. This is a two zone system: it contains five, 600 m2 pinning rooms for the growing phase on one side of the working hall, and five harvesting rooms of the same size on the other side. The mushroom beds are transferred to the harvesting rooms a day prior to harvesting. Crates are automatically conveyed to and from the harvesting stations. Each growing room contains two picking stations, and three people work at each station. This new method enables pickers to harvest with two hands, maximising the picking performance. The stems are also cut automatically.